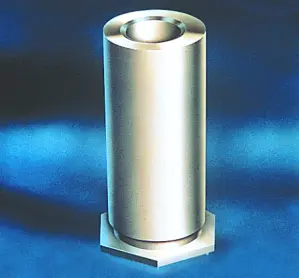

Self-Clinching Standoffs

Click image to enlarge

Self-clinching standoffs provide a solution when design engineers need to space panels and components in their metal enclosures. They are used to stack parts or keep components a defined distance from the panel in which they are installed.

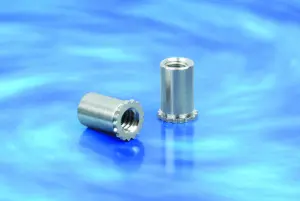

Captive Fastener’s clinch standoffs are available in a blind thread or a through thread to meet any application requirements. Use a standoff where the design calls for the standoff to be installed through the exterior of the enclosure. Use a through-thread (also called a thru-hole) clinch standoff to create a flush outer appearance.

Find the Right Self-Clinching Standoff for Your Project

Self-Clinching Standoff Applications

Self-clinching standoffs are ideal for applications requiring panels or other components to be mounted, spaced, or stacked. These clinch standoffs are well-suited to many projects within a wide range of industries, including:- Compact Electronics

- Printed Circuit Boards

- Modems

- And many more.

Installing a Self-Clinching Standoff

Our self-clinching standoffs are to be installed into ductile material, allowing the metal to flow into the clinch profile of the standoff and create a permanent reusable thread in the assembly. The fasteners must be sufficiently harder than the panels into which they will be installed. After each self-clinching standoff component is fitted into a properly sized hole in the mating panel, the standoffs are then pressed into place using a squeezing force. Some of our standoffs feature spring top heads for easier attachment and removal.You can determine the proper hole sizes and suggested installation force by visiting our catalog.

Advantages of Using Self-Clinching Standoffs

Our self-clinching standoffs provide a low installation cost and a strong reusable thread in sheets as thin as .040” thick.Clinch standoffs eliminate the possibility of loose hardware in the assembly, which is particularly important for applications such as electronic enclosures and cabinetry.Self-clinching standoffs provide excellent push-out and torque-out values that meet or exceed industry standards. The design allows the clinch standoff to retain its dimensional integrity during the clinch process. Unlike a swage fastener or rivet, clinch standoffs do not deform around the panel while maintaining REACH and RoHS compliance.

High-Quality Self-Clinching Standoff Materials

We offer clinch standoffs in a variety of materials to meet the needs of the engineer. Our experts are here to discuss your unique application requirements to find the best self-clinching standoff material for you. We offer blind thread or through thread clinch standoffs made from:- Steel

- Stainless steel

- Aluminum